Stainless Steel Single Stage Centrifugal Pump

XMS stainless steel single stage centrifugal pump is newly-designed based on using advanced technologies. The pump is found in many applications, which include

Pressurization and pumping of industrial and civilian clean water or other liquids

Water treatment

Water circulating system

Irrigation

Other fields

Motor

TEFC motor, 2-pole

Protection class: IP55

Insulation class: 155

Standard voltage: 50Hz, 1×220V, 3×380V×220V

Features of Stainless Steel Single Stage Centrifugal Pump

It is single-stage centrifugal pump featuring axial suction and radial discharge

Compact structure, coaxial installation

The pump is directly connected with the motor

Easy use, simple installation, threaded inlet and outlet

Light weight, thin plate pressing structure for main parts and components

Corrosion resistance, components contacting pumped liquid are made of AISI304 or AISI316 stainless steel

Pumped mediums

Fluids should be thin, clean, non-flammable and explosive, with no solid particles and fibers

Able to transfer the medium with slight corrosion

Use a motor with a higher output power rating when the density of transmitted medium is higher than that of clean water

Operating Conditions

Liquid temperature -10℃ ~ +85℃

Ambient temperature: up to +40℃

Altitude: up to 1000m

Max. operating pressure: 8 bar

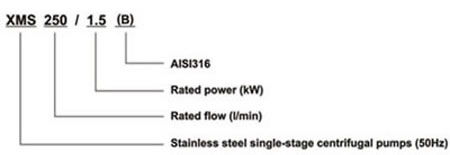

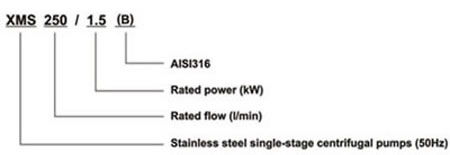

Identification Codes

Installation Requirements of Stainless Steel Standard Centrifugal Pump

It is comprised of pump, pump shaft and standard motor. The pump and the shaft are joined directly.

The pump should be installed on the ventilating and anti-freezing place.

The pump should be installed in a way that the pump will not be influenced by the tension of the pipeline.

If the pump is installed outdoors, it must equip a suitable outer cover to prevent electric components from water inflow or dew.

During installation, enough space should be left around the pump unit to facilitate inspection and maintenance.

Electric wiring device protect the pump from being damaged by lack of phase, unstable voltage, current leakage or overload.

The pump should be installed on the pedestal horizontally. Horizontal direction is the inlet for the pump, and vertical direction is the outlet for the pump.

Guidelines to Performance Curves

Tolerance to ISO 9906, Annex A.

All curves have been made with 3×380V and the constant speed of 2850rpm.

Measurements have been made with airless water at a temperature of 20℃ and kinematic viscosity of 1mm2/s.

Refer to the performance range for the operation of the pump to prevent the motor from overloading caused by too large of a flow rate.

Hydraulic Performance Ranges of 50HZ

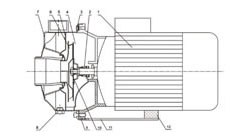

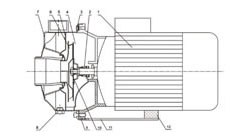

Cross Secti on

on

Hydraulic Performance Data

| Type |

Stainless Steel Single-Stage Centrifugal Pumps |

| Model |

Power |

Q(l/

min) |

20 |

40 |

60 |

80 |

100 |

120 |

140 |

160 |

200 |

250 |

300 |

330 |

350 |

400 |

450 |

Q(m3

/h) |

1.2 |

2.4 |

3.6 |

4.8 |

6.0 |

7.2 |

8.4 |

9.6 |

12 |

15 |

18 |

20 |

21 |

24 |

27 |

| XMS60/0.37 |

0.37 |

H

(m) |

17.7 |

16.4 |

14.6 |

11.4 |

|

|

|

|

|

|

|

|

|

|

|

| XMS60/0.55 |

0.55 |

22.7 |

21.3 |

19.5 |

16.2 |

|

|

|

|

|

|

|

|

|

|

|

| XMS60/0.75 |

0.75 |

28.2 |

26.8 |

25 |

22 |

|

|

|

|

|

|

|

|

|

|

|

| XMS100/0.55 |

0.55 |

|

17.8 |

16.7 |

15.4 |

14 |

12.2 |

9.9 |

|

|

|

|

|

|

|

|

| XMS100/1.1 |

1.1 |

|

27.4 |

26.3 |

25 |

23.4 |

21.5 |

19.5 |

16.7 |

|

|

|

|

|

|

|

| XMS160/0.75 |

0.75 |

|

|

15.5 |

15.3 |

19.3 |

14.8 |

14.3 |

13.8 |

12.5 |

|

|

|

|

|

|

| XMS160/1.1 |

1.1 |

|

|

19.7 |

19.5 |

15.8 |

19.1 |

18.7 |

18.2 |

16.5 |

|

|

|

|

|

|

| XMS250/1.1 |

1.1 |

|

|

|

|

23.2 |

15.6 |

15.4 |

15 |

14.3 |

13 |

11.5 |

|

|

|

|

| XMS250/1.5 |

1.5 |

|

|

|

|

28.2 |

23 |

22.7 |

22.2 |

21.4 |

19.8 |

17.7 |

|

|

|

|

| XMS250/2.2 |

2.2 |

|

|

|

|

|

27.8 |

27.5 |

27 |

26.2 |

24.6 |

22.6 |

|

|

|

|

| XMS330/1.5 |

1.5 |

|

|

|

|

|

18.8 |

18.7 |

18.5 |

17.8 |

16.7 |

15 |

14 |

13.5 |

11.6 |

|

| XMS330/2.2 |

2.2 |

|

|

|

|

|

22.5 |

22.2 |

22 |

21.5 |

20.3 |

18.7 |

17.5 |

16.8 |

14.8 |

12.3 |

Table of Materials

| |

Part |

Material |

References Standard |

| 1 |

Motor |

|

|

| 2 |

Mechanical seal |

Ceramic/carbon |

|

| 3 |

M6×15 / Screw |

0Cr18Ni9/ SS304 |

AISI304 |

| 4 |

Seal base |

0Cr18Ni9/ SS304 |

AISI304 |

| 5 |

Diffuser |

0Cr18Ni9/ SS304 |

AISI304 |

| 6 |

Impeller |

0Cr18Ni9/ SS304 |

AISI304 |

| 7 |

Pump body |

0Cr18Ni9/ SS304 |

AISI304 |

| 8 |

Drainage plug |

0Cr18Ni9/ SS304 |

AISI304 |

| 9 |

M6×20 / Screw |

0Cr18Ni9/ SS304 |

AISI304 |

| 10 |

Nut M10 |

0Cr18Ni9/ SS304 |

AISI304 |

| 11 |

Base |

Steel |

A570 |

| 12 |

Support |

NBR |

|

Hydraulic Performance Curve and Installation Dimensions

Hydraulic Performance Curve and Installation Dimensions

LEO is a professional single stage centrifugal pump manufacturer and supplier in China. We provide a wide range of products, including peripheral pumps, centrifugal pumps, garden shredders and snow throwers etc. Thanks to their high quality and low prices, they are very popular in the global markets and sold to countries such as the USA, Korea, Canada, Mexico, Britain, India, Australia, Israel, Iraq, and Peru etc.

We are looking forward to helping customers both at home and abroad satisfy their needs for various water pumps and garden machines.

Hydraulic Performance Curve and Installation Dimensions

Hydraulic Performance Curve and Installation Dimensions